top of page

RESOURCES

Support Services

Instructions

Pull Down & Data Acquisition Support Services.pdf

Customer Bearing Spacer Form.pdf

Hub Bearing Spacer Instructions.pdf

Precision Bearing Packer Instructions.pdf

Alignment System Ordering Form.pdf

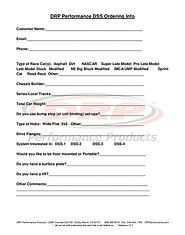

Data Acquisition System Ordering Form.pdf

DSS System Ordering Form.pdf

Technical Articles

Hub End Play Chart

GM Caliper Mount Jig Instructions.pdf

Dual Axis Caster/Camber Gauge Instructions.pdf

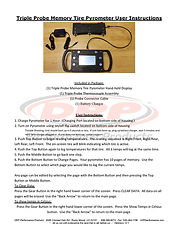

Triple Probe Memory Tire Pyrometer Instructions.pdf

Suspension Analysis Downloads

DRP DSS System Comparison.pdf

DRP Performance Equipment Terms.pdf

DSS Report Sample.pdf

Videos

DSS & Alignment Systems

DSS & Alignment Systems

Top 3 Reasons to Buy a DRP Pull Down System

00:28

Play Video

Get Fast, Faster with DRP Set Up Tools & Equipment

01:46

Play Video

DSS 4 Updated Start-Up Procedure

08:15

Play Video

DRP University Tutorials

DRP University Tutorials

What is DRP University?

01:10

Play Video

Our Greatest Product..!

01:40

Play Video

DRP DSS-3 Pull Down System.wmv

03:29

Play Video

bottom of page